0.2mm 0.7mm Dikte Verskaffers Prys H32 1mm Legering Aluminium Spoel

| 1) 1000-reekslegering (algemeen genoem kommersiële suiwer aluminium, Al> 99.0%) | |

| Suiwerheid | 1050 1050A 1060 1070 1100 |

| Temperament | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/ H26/H36 H18/H28/H38 H114/H194, ens. |

| Spesifikasie | Dikte ≤30 mm; Breedte ≤2600 mm; Lengte ≤16000 mm OF Spoel (C) |

| Toepassing | Dekselvoorraad, industriële toestelle, berging, alle soorte houers, ens. |

| Kenmerk | Hoë geleidingsvermoë, goeie korrosiebestande werkverrigting, hoë latente hitte van smelt, hoë weerkaatsing, goeie sweiseienskappe, lae sterkte, en nie geskik vir hittebehandelings. |

| 2) 3000-reeks legering (algemeen genoem Al-Mn-legering, Mn word as hooflegeringselement gebruik) | |

| Legering | 3003 3004 3005 3102 3105 |

| Temperament | O/H111 H112 H12/H22/H32 H14/H24/H34 H16/H26/ H36 H18/H28/H38 H114/H194, ens. |

| Spesifikasie | Dikte ≤30 mm; Breedte ≤2200 mm Lengte ≤12000 mm OF Spoel (C) |

| Toepassing | Versiering, hitteafvoertoestel, buitemure, berging, plate vir konstruksie, ens. |

| Kenmerk | Goeie roesbestandheid, nie geskik vir hittebehandelings nie, goeie korrosiebestandheid werkverrigting, goeie sweiseienskappe, goeie plastisiteit, lae sterkte maar geskik vir koue werkverharding |

| 3) 5000-reeks legering (algemeen genoem Al-Mg-legering, die Mg word as hooflegeringselement gebruik) | |

| Legering | 5005 5052 5083 5086 5182 5754 5154 5454 5A05 5A06 |

| Temperament | O/H111 H112 H116/H321 H12/H22/H32 H14/H24/H34 H16/H26/H36 H18/H28/H38 H114/H194, ens. |

| Spesifikasie | Dikte ≤170 mm; Breedte ≤2200 mm; Lengte ≤12000 mm |

| Toepassing | Mariene Graad Plaat, Ring-Trek Blik-Eind Voorraad, Ring-Trek Voorraad, Motor Bakplate, motor binnebord, die beskermende bedekking op die enjin. |

| Kenmerk | Al die voordele van normale aluminiumlegering, hoë treksterkte en vloeigrens, goeie korrosiebestande werkverrigting, goeie sweiseienskappe, goeie moegheidssterkte, en geskik vir anodiese oksidasie. |

| 4) 6000-reekslegering (algemeen genoem Al-Mg-Si-legering, die Mg en Si word as hooflegeringselemente gebruik) | |

| Legering | 6061 6063 6082 |

| Temperament | VAN, ens. |

| Spesifikasie | Dikte ≤170 mm; Breedte ≤2200 mm; Lengte ≤12000 mm |

| Toepassing | Motorvoertuie, Aluminium vir Lugvaart, Industriële Vorm, Meganiese Komponente, Vervoerskip, halfgeleiertoerusting, ens. |

| Kenmerk | Goeie korrosiebestande werkverrigting, goeie sweiseienskappe, goeie oksideerbaarheid, maklik om te spuitafwerk, goeie oksidasiekleuring, goeie bewerkbaarheid. |

As 'n liggewig, korrosiebestande materiaal word aluminiumspoele wyd gebruik in verskeie velde.

Eerstens, in die konstruksiebedryf word aluminiumspoele dikwels gebruik in die versiering van buitemure, dakke, plafonne, vensterrame, ens. Omdat aluminiumspoele goeie weerbestandheid en dekoratiewe eienskappe het, kan hulle aan die voorkoms- en duursaamheidsvereistes van geboue voldoen.

Tweedens, in die vervoerbedryf word aluminiumspoele dikwels gebruik om doppe, bakpanele, binneonderdele, ens. van voertuie soos motors, treine en vliegtuie te vervaardig. Die liggewig-aard van aluminiumspoele help om die totale gewig van die voertuig te verminder en brandstofdoeltreffendheid te verbeter.

Daarbenewens word aluminiumspoele op die gebied van elektroniese en elektriese toestelle dikwels gebruik om batterykaste, verkoelers, elektroniese produkomhulsels, ens. te vervaardig. Die elektriese geleidingsvermoë en hitte-afvoer-eienskappe van aluminiumspoele maak dit 'n belangrike materiaal in die elektroniese en elektriese industrie.

Daarbenewens word aluminiumspoele ook wyd gebruik in voedselverpakking, farmaseutiese verpakking, ens. op die gebied van verpakking. Omdat aluminiumspoele goeie verseëling- en oksidasiebestandheid het, kan hulle die kwaliteit en veiligheid van verpakte items effektief beskerm.

Oor die algemeen het aluminiumspoele belangrike toepassings in konstruksie, vervoer, elektroniese toestelle, verpakking en ander velde. Die ligte gewig, korrosiebestandheid en maklike verwerking maak dit een van die onontbeerlike materiale in verskeie industrieë.

Nota:

1. Gratis monsterneming, 100% na-verkope gehalteversekering, Ondersteun enige betaalmetode;

2. Alle ander spesifikasies van ronde koolstofstaalpype is beskikbaar volgens u vereiste (OEM & ODM)! Fabrieksprys wat u van ROYAL GROUP sal kry.

| BREEDTE (MM) | (mm) | (mm) | (mm) | (mm) | (mm) |

| 1000 | 1 | 2 | 3 | 4 | Ander |

| 1219 | 1 | 2 | 3 | 4 | Ander |

| 1220 | 1 | 2 | 3 | 4 | Ander |

| 1500 | 1 | 2 | 3 | 4 | Ander |

| 2000 | 1 | 2 | 3 | 4 | Ander |

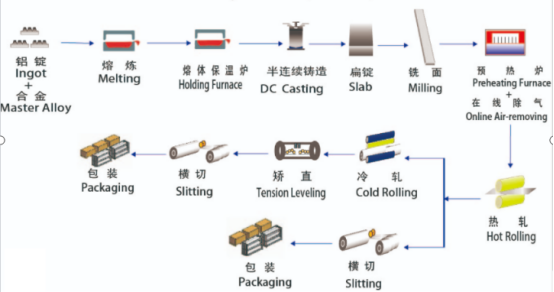

Die produksieproses van aluminiumspoele sluit gewoonlik verskeie stappe in, soos die voorbereiding van grondstowwe, die smelt van aluminiumvloeistof, die deurlopende giet en rol, die blus en uitgloeiing, en die behandeling van bedekkings.

Eerstens, in die voorbereidingsfase van die grondstof, word aluminiumblokke gewoonlik as grondstowwe gebruik tydens die produksie van aluminiumspoele. Aluminiumblokke ondergaan toetsing, smelting, semi-deurlopende gieting en ander prosesse om vloeibare aluminium te verkry wat aan die vereistes voldoen.

Volgende is die deurlopende giet- en rolstadium, waar die gesmelte aluminium in aluminiumplate gegiet word, wat dan deur 'n deurlopende rolmeul gerol word om die dikte geleidelik te verminder om die vereiste aluminiumspoele te vorm.

Dit word gevolg deur 'n blus- en gloeibehandeling. Deur die aluminiumspoel te blus en te gloei, word die struktuur en eienskappe daarvan aangepas, en die sterkte en plastisiteit daarvan word verbeter.

Die laaste stap is die behandeling van die laag. Aluminiumspoele kan behandel word met anti-korrosie, dekoratiewe bedekkings, ens. om aan verskillende gebruiksbehoeftes te voldoen.

Die hele produksieproses sluit ook daaropvolgende prosesse soos sny, oprol en verpakking van produkte in, en verkry uiteindelik afgewerkte aluminiumspoele wat aan die kliënt se vereistes voldoen.

Elke aspek van die aluminiumspoelproduksieproses moet streng beheer word om te verseker dat produkgehalte en -prestasie aan standaardvereistes voldoen. Terselfdertyd is omgewingsbeskerming, energieverbruik en ander aspekte ook kwessies waarop tydens die produksieproses gefokus moet word.

As 'n belangrike industriële grondstof moet aluminiumspoele behoorlik verpak en vervoer word nadat produksie voltooi is om die veiligheid en integriteit van die produk te verseker.

Die eerste is die verpakkingsproses, wat gewoonlik in houtpalette of kartonne verpak word. Vir groot aluminiumspoele word houtpalette dikwels vir verpakking gebruik. Die aluminiumspoele word netjies op die houtpallet gestapel en met plastiekfilm of verpakkingsband vasgemaak om skudding en botsing tydens vervoer te voorkom. Vir klein aluminiumspoele word hulle gewoonlik in kartonne verpak, en die aluminiumspoele word in die karton geplaas en aan die buitekant versterk om die produkoppervlak teen skade te beskerm.

Volgende is die vervoerskakel. Aluminiumspoele word gewoonlik per land, see of spoor vervoer. Tydens vervoer moet sorg gedra word om reën, direkte sonlig en hoë temperature te vermy om die kwaliteit van die produkoppervlak te beïnvloed. Vir langafstandversending is vogbestande en roesbestande werk ook nodig om die veiligheid van produkte tydens langafstandvervoer te verseker.

Tydens die verpakkings- en vervoerproses is dit nodig om streng die toepaslike standaarde en regulasies na te kom om die veiligheid en integriteit van die produk te verseker. Terselfdertyd vereis aluminiumspoele van verskillende spesifikasies en gebruike verskillende verpakkings- en vervoermetodes om aan kliëntebehoeftes en produkeienskappe te voldoen.

Vervoer:Ekspres (Monsteraflewering), Lug, Spoor, Land, Seevervoer (FCL of LCL of Bulk)

V: Is ua vervaardiger?

A: Ja, ons is 'n vervaardiger. Ons het ons eie fabriek in Tianjin City, China. Boonop werk ons saam met baie staatsbeheerde ondernemings, soos BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, ens.

V: Kan ek 'n proefbestelling van slegs 'n paar ton kry?

A: Natuurlik. Ons kan die vrag vir u verskeep met LCL-diens. (Minder houerlading)

V: Indien monster gratis?

A: Monster gratis, maar die koper betaal vir die vrag.

V: Is u goudverskaffer en doen u handelsversekering?

A: Ons is sewe jaar goudverskaffer en aanvaar handelsversekering.